Understanding Liquid Silver Mercury Manufacturers

Liquid mercury, often referred to as liquid silver due to its shiny appearance, has several applications across various industries. As a vital part of scientific fields and industrial applications, it is essential to understand the role and reputation of liquid silver mercury manufacturers in providing high-quality mercury. This article will delve into the intricacies of mercury production, its various uses, and guidelines for finding reliable manufacturers.

The Significance of Liquid Mercury in Modern Industries

Liquid mercury has been an invaluable resource in numerous applications. It is primarily used in:

- Scientific Research: Mercury is a key component in many scientific instruments such as barometers, thermometers, and sphygmomanometers.

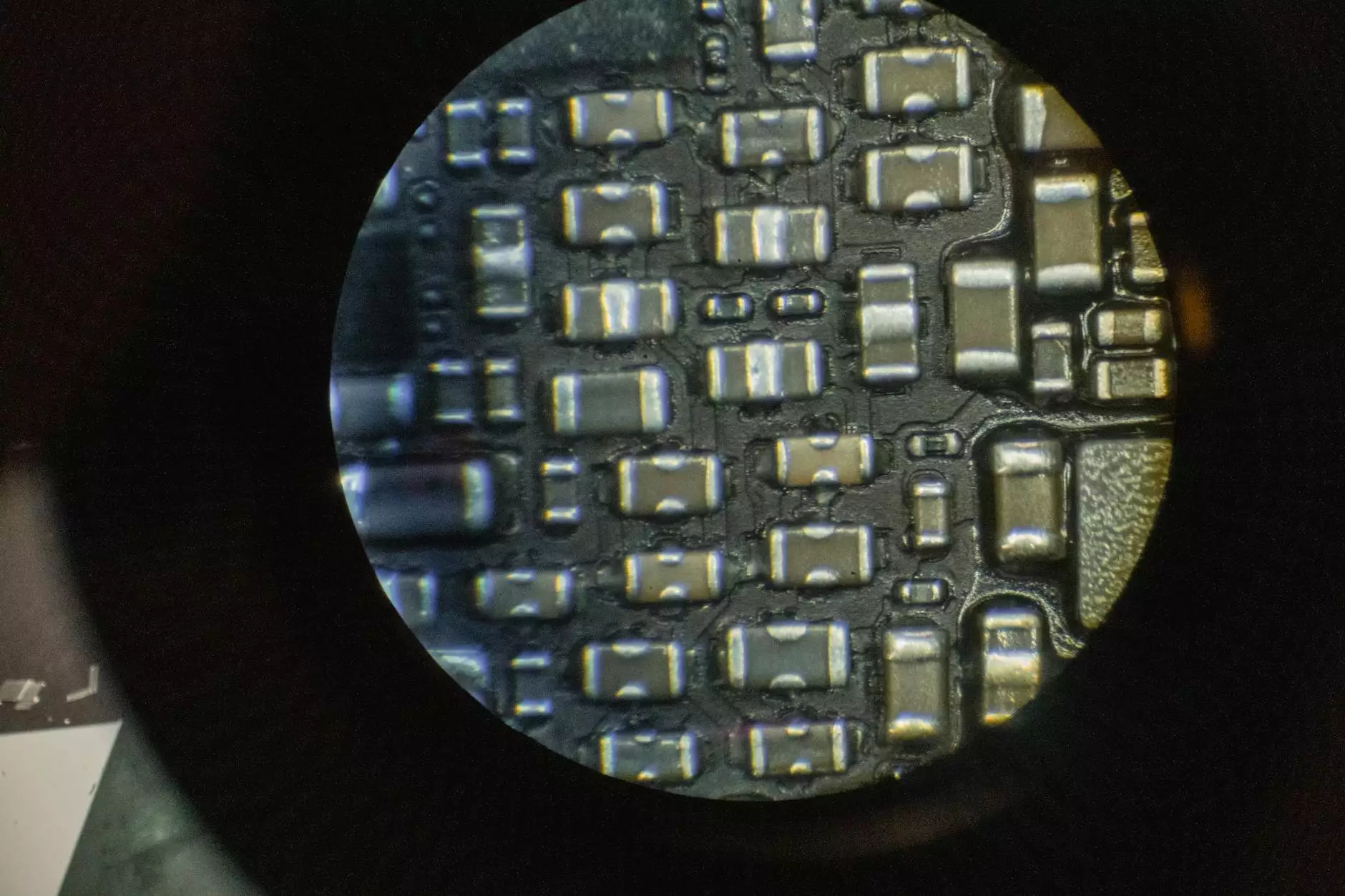

- Electronics Manufacturing: Mercury is utilized in the production of various electronic components and helps in maintaining stable electrical performance.

- Dental Applications: Dental amalgams made with mercury are commonly used in various dental procedures due to their durability and effectiveness.

- Mining Operations: Mercury is utilized in gold mining to extract gold from ores, a process known as amalgamation.

Identifying Quality Liquid Silver Mercury Manufacturers

With many manufacturers claiming to provide high-grade liquid mercury, how can one discern the best? Here are some crucial factors to consider:

1. Compliance with Safety Standards

First and foremost, ensure that any manufacturer complies with local and international safety and environmental regulations. ISO certifications and adherence to protocols set by the Environmental Protection Agency (EPA) are essential indicators of a reputable manufacturer.

2. Quality Assurance Practices

High-quality manufacturers implement rigorous quality assurance measures during production. They should conduct thorough testing of their products to ensure the absence of impurities and maintaining the required standards. Look for manufacturers who provide detailed product specifications and certificates of analysis.

3. Transparency in Sourcing and Production

Reputable manufacturers should be transparent about their sourcing methods and production processes. This includes disclosing the origin of their mercury and the methods utilized in refining it to ensure purity.

4. Customer Testimonials and Reviews

Investigate customer feedback and reviews regarding the manufacturer. Reliable liquid silver mercury manufacturers typically have a strong track record with satisfied clients. Look for ratings on independent review platforms and industry-specific forums.

The Process of Producing Liquid Silver Mercury

The journey of liquid mercury from nature to a usable product involves several critical steps:

1. Extraction from Ores

Mercury is primarily extracted from cinnabar ore through a process that includes roasting the ore to release mercury vapors, which are subsequently condensed into liquid mercury.

2. Refinement

After extraction, the raw mercury undergoes a refining process. This stage is crucial for removing impurities and achieving the high purity levels required for various applications. Thorough refinement yields mercury of superior quality.

3. Quality Testing

Post-refinement, the mercury is subjected to in-depth quality testing. Advanced analytical techniques, such as atomic absorption spectroscopy, are employed to measure the purity and content, ensuring it meets industry standards.

4. Packaging and Distribution

Finally, the liquid mercury is packaged in secure, safe containers to prevent contamination during transportation. Manufacturers should ensure that their logistics adhere to regulatory standards to avoid environmental hazards.

Key Applications of Liquid Mercury

1. Scientific Applications

In scientific research, the properties of liquid mercury make it an ideal candidate for precise measurements. Its ability to expand uniformly with temperature changes makes it invaluable in calibrating instruments.

2. Industrial Uses

In industries, liquid mercury plays a pivotal role in processes such as electrical contacts and switches, ensuring stability and efficiency in operations.

3. Health and Dental Practices

Despite past controversy, mercury-containing dental amalgams remain popular in dentistry due to their durability. However, the debate around their safety continues, emphasizing the need for high-quality mercury from trustworthy manufacturers.

4. Environmental Impact and Mining

While mercury is beneficial in various fields, its environmental impact is a growing concern. Responsible usage and sourcing from liquid silver mercury manufacturers who prioritize sustainability and minimize environmental harm are paramount.

Challenges Faced by Mercury Manufacturers

The industry of liquid mercury manufacturing faces several challenges:

1. Regulatory Restrictions

Increasing regulations surrounding mercury usage due to its toxicity limit the market for mercury manufacturers. Adaptation to comply with changing laws is critical.

2. Public Perception

Public awareness of the dangers associated with mercury has led to declining demand in certain sectors and a need for manufacturers to educate their consumers proactively.

3. Competition from Alternatives

With the rise of alternative materials for many applications previously dominated by mercury, manufacturers must innovate and explore new markets to maintain relevance.

Future Trends in Mercury Manufacturing

The future of liquid mercury manufacturing is evolving. With ongoing research and growing emphasis on sustainable practices, we can expect to see:

1. Enhanced Safety Protocols

As awareness of mercury's environmental and health impacts increases, manufacturers will need to adopt enhanced safety protocols and invest in cleaner technologies for production.

2. Focus on Recycling

The recycling of mercury will become more prominent, minimizing environmental impact and meeting regulatory demands. Manufacturers will benefit from developing circular economy practices.

3. Technological Advancements

Advancements in extraction and refining technologies will improve yield and purity levels, making liquid mercury production more efficient and less hazardous.

Conclusion: Choosing Reliable Liquid Silver Mercury Manufacturers

In summary, the role of liquid silver mercury manufacturers is critical in providing high-quality mercury for various applications. By understanding and applying the insights discussed, consumers can make informed decisions when sourcing mercury. Always prioritize quality, safety, and ethical sourcing when dealing with mercury. For those seeking liquid mercury for sale, it is recommended to look for manufacturers with a proven track record, adhere to regulatory standards, and demonstrate transparency in their operations. Visit dschemek.com for reliable supply options and additional information on liquid mercury.